PVC FOAM

CLOSED CELL FOAM

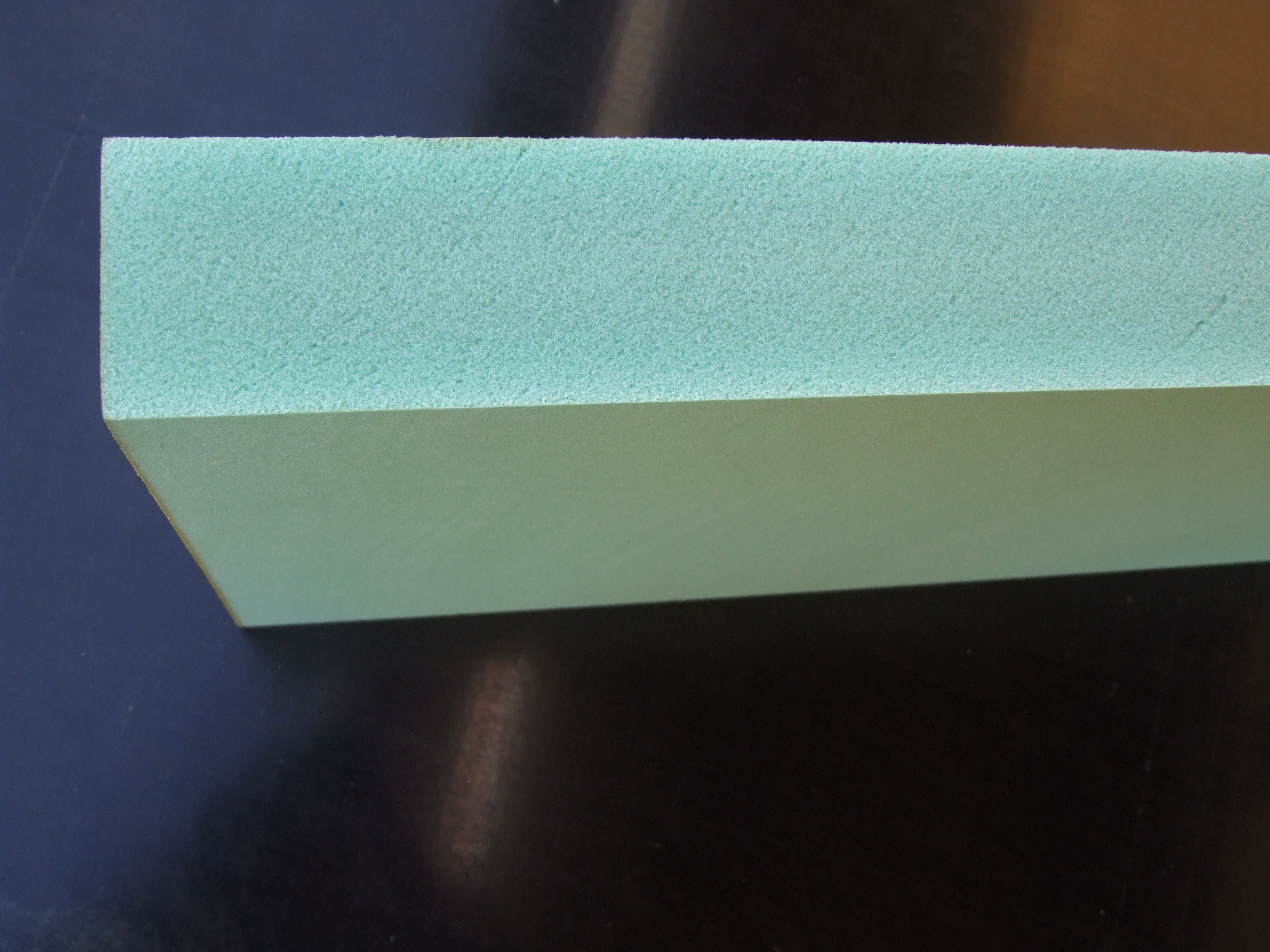

Rigid foam used as the core of sandwich structures for high-performance composite materials. The foam is made of 100% closed polyhedral cellular cross-linked PVC, free of chlorofluorocarbons.

PVC Core materials offer a wide range of products already in the evaluation and design phase. In addition, our service covers the entire process up to the production of a lightweight sandwich component adapted to individual customer requirements, including cutting in thickness, width and length. All finishes are additionally available. Our services are tailored to the client's requirements and are cost-effective and environmentally friendly. We cooperate with various institutes, universities, and development companies.

PVC foam is used for all composite applications and is compatible with all common resin systems including epoxy, polyester and vinylester resins.

Lastnosti PVC pene: Izjemna mehanska odpornost in trdnost v razmerju s težo, odlična zvočna in toplotna izolacija, dobra kemična odpornost, enostavna obdelava, nizka absorpcija smole, dimenzijsko stabilna za zaviranje požara, nizka absorpcija vode, dimenzijsko stabilna, dobre tlačne in strižne lastnosti. 932 / 5.000 Properties of PVC foam: Exceptional mechanical resistance and strength in relation to weight, excellent sound and thermal insulation, good chemical resistance, easy processing, low resin absorption, dimensionally stable for fire retardancy, low water absorption, dimensionally stable, good pressure and shear properties. We have PVC foam in quality (1st quality) and Lycell (glued foam). Sandwich structures are lighter using PVC foam 505. In the field of wind energy, PC foams provide a better balance between strength and weight, which allows for larger rotor blades and consequently increased performance and durability. We prepare all PVC foam in thicknesses from 1.8 mm to 72 mm (depending on density) and in densities from 40 kg/m3 to 250 kg/m3. We provide all additional services for PVC panels: reinforced mesh + channels, channels (one-sided / two-sided), perforation, knife cut... PVC foam has obtained the GL (Germanischer Llyod) industrial certificate.

We offer foam depending on the density (kg/m3), namely: M040, M048, M060, M080, M100, M130, M200, M250. PVC foam can be used in all forms of resin infusion and is compatible with polyester, vinylester and epoxy resin systems. Low absorption properties ensure better infusions, low resin costs and low weight.

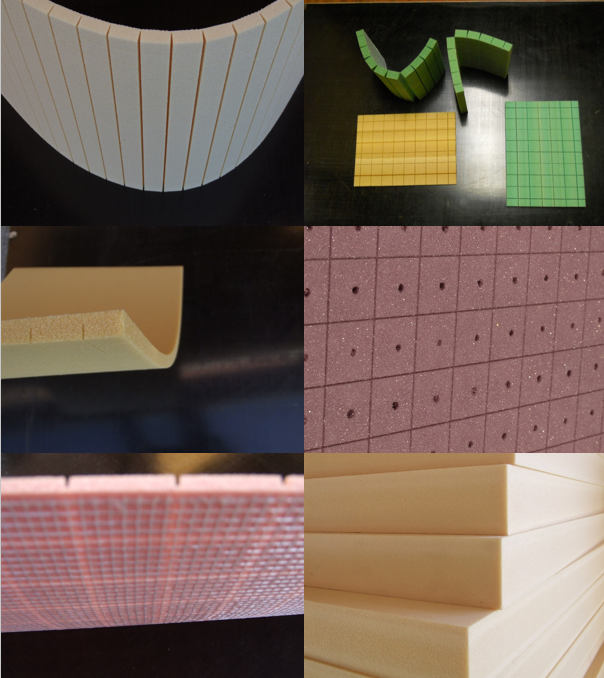

WE ARE PROCESSING PVC FOAM FOR YOU

Slizing in different dimensions

All PVC foam is prepared in thickness from 3mm to 72mm (depending on density) and in density from 40 kg/m3 to 250 kg/m3.

Warehousing

We store large quantities, so we can enable you to order in smaller quantities and you do not need to have your own warehouse. We are on demand.

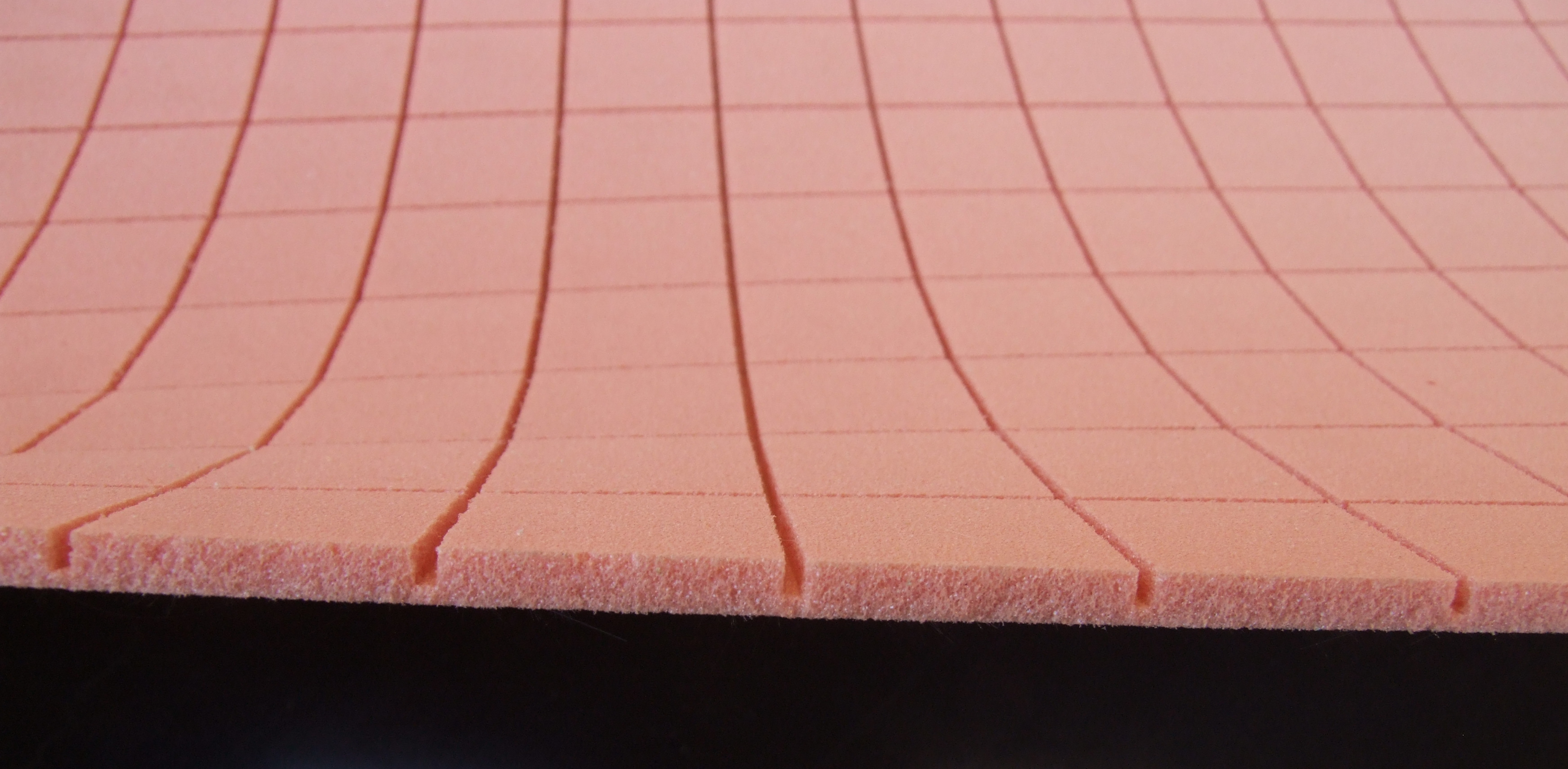

Single and double cut

Provides flexibility in a single or double direction on one or both sides of a sheet. If done on both sides, the cuts intersect so no bleeder holes are necessary for vacuum bagging.

Knife cut

The cuts are not visible, as the knives are 0.45 mm thick. When the sheet lie flat and the narrow knife cuts reduce unnecessary resin build-up compared to cououts with a saw.

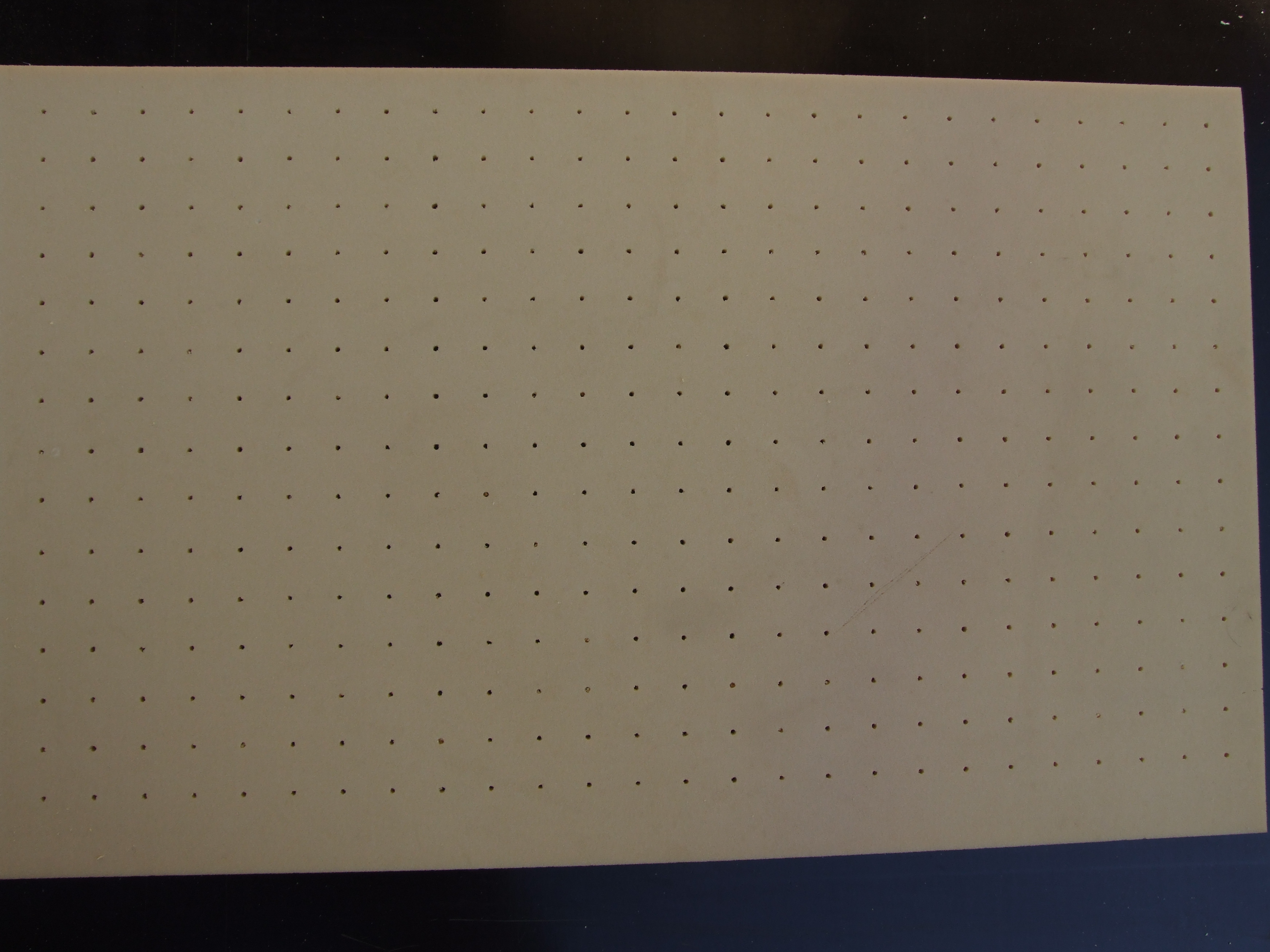

Perforation

With a drilling machine, the foam can be pierced as desired, for easier resin injection. The perforation can be combined with knife cut, channel cutting and glass fabric. Possible holes thickness 11,2 mm, 2 mm ali 2,8 mm.

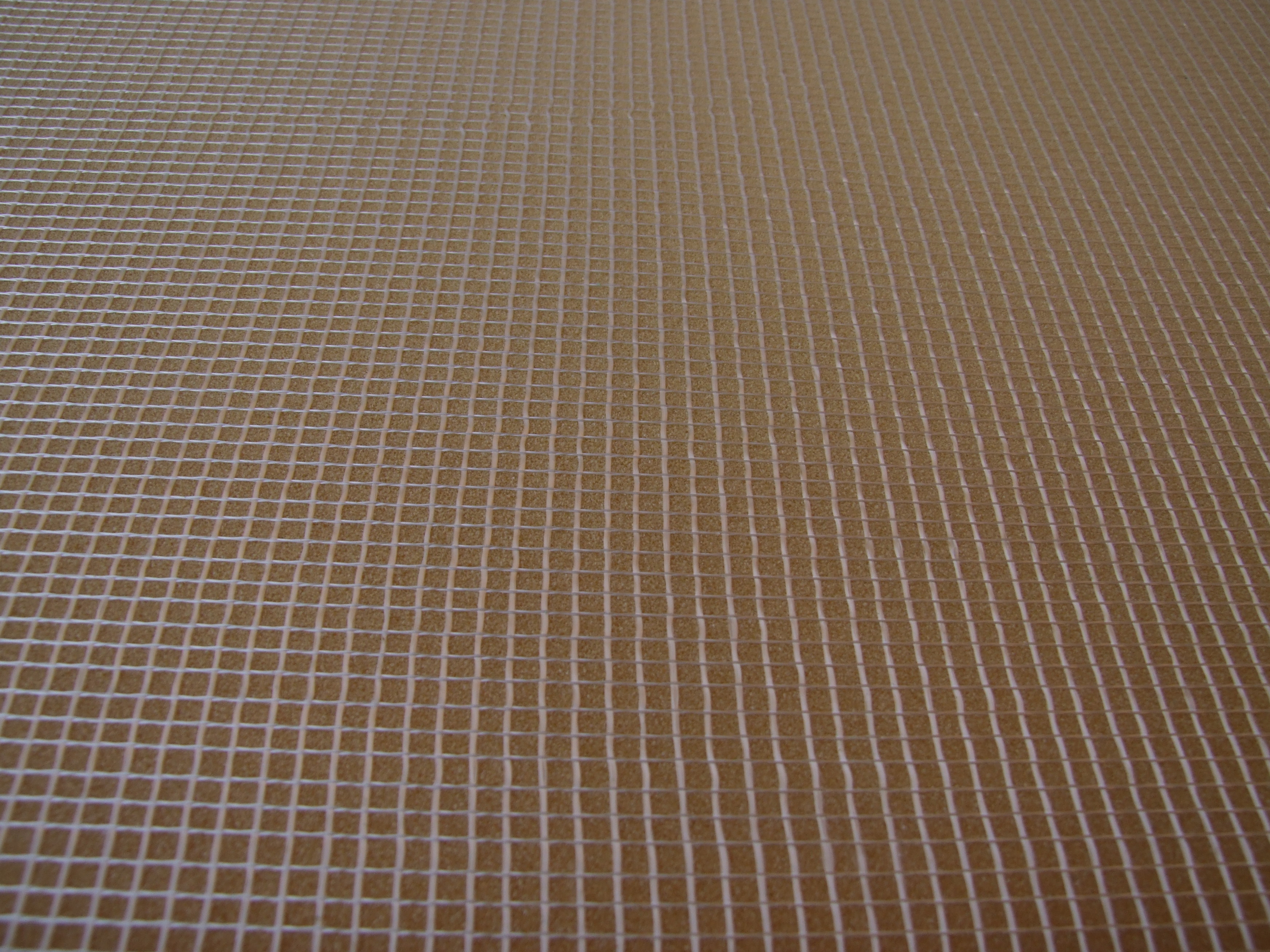

Fiberglass fabric

The glass fabric is glued to the foam to increase the compactness of the sheet. The disintegration of the board is prevented and this enables a deeper cutting of the board or knife cut.